HIGHLIGHTS

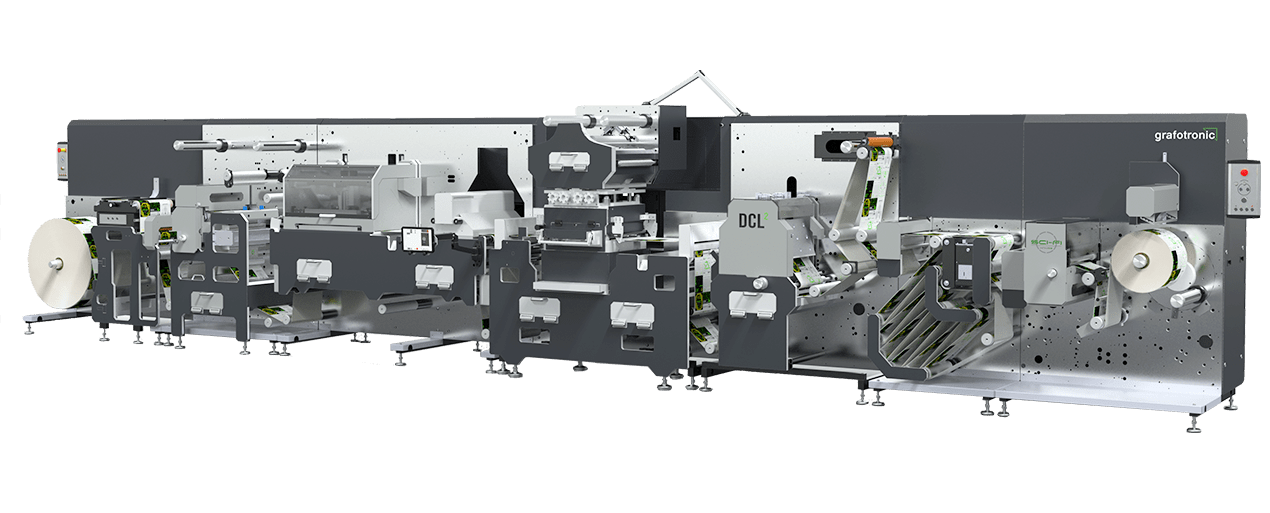

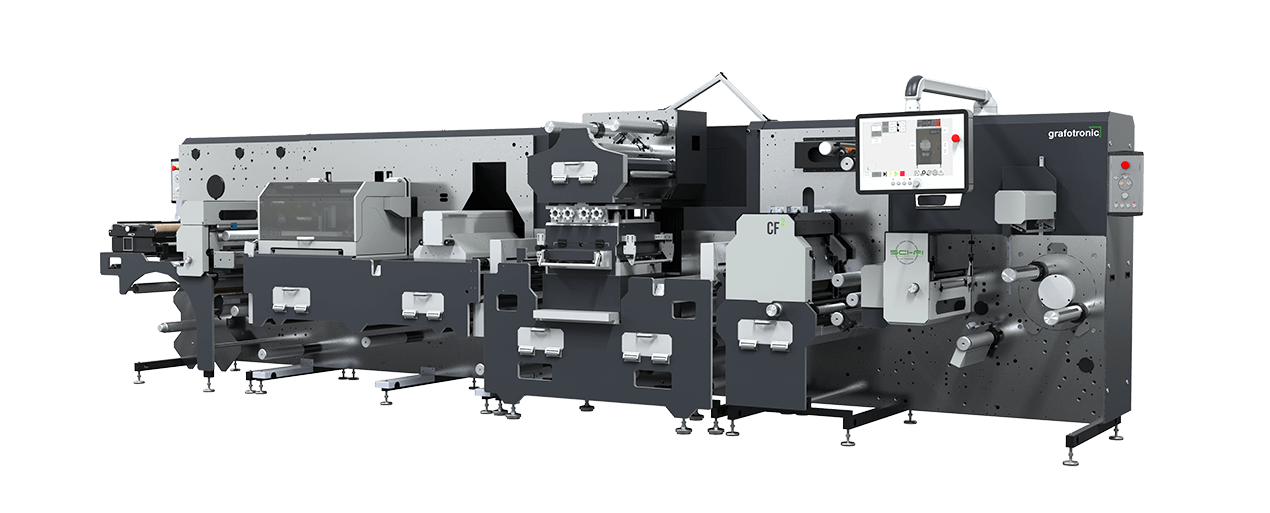

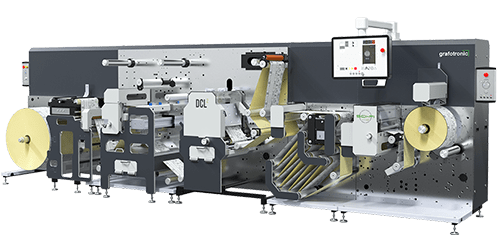

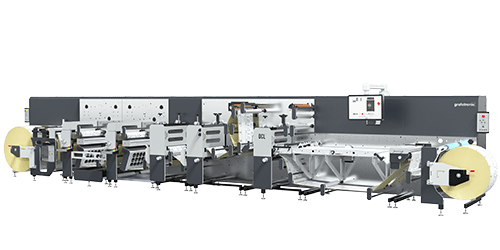

- Simple, versatile, and compact in operation for complex uses

- Digital spot varnish or full range of foil effects

- Compatible with wide range of materials and substrates, enabling applications onto labels, tags, tickets, forms and security products

- Enables application of variable content such as text, security marks and graphics

- Completely toolless operation

- Perfect solution for high-end embellishing of short run work