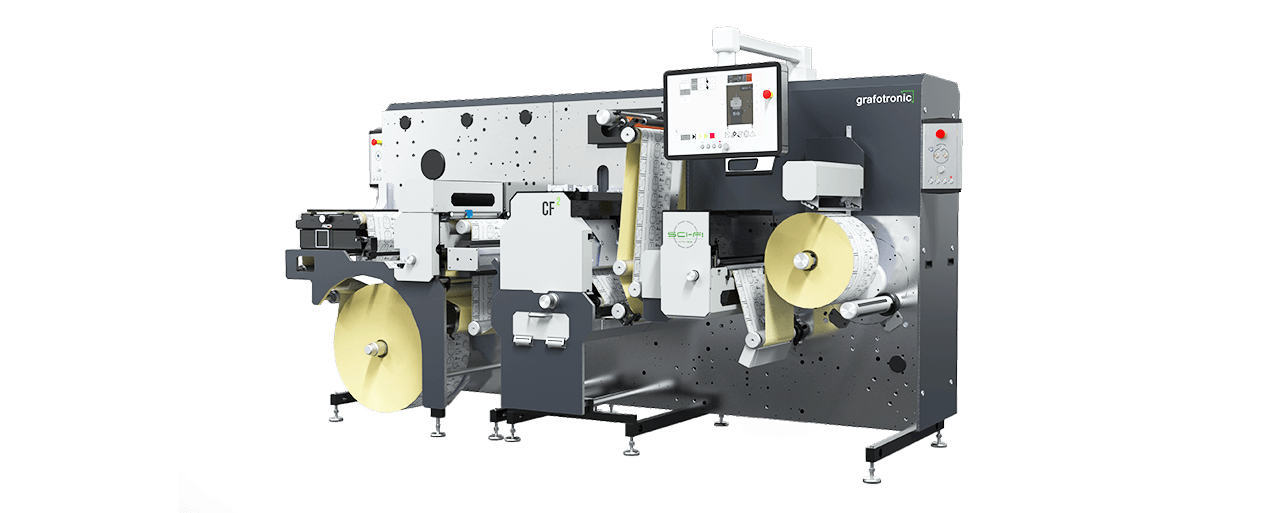

Highlights

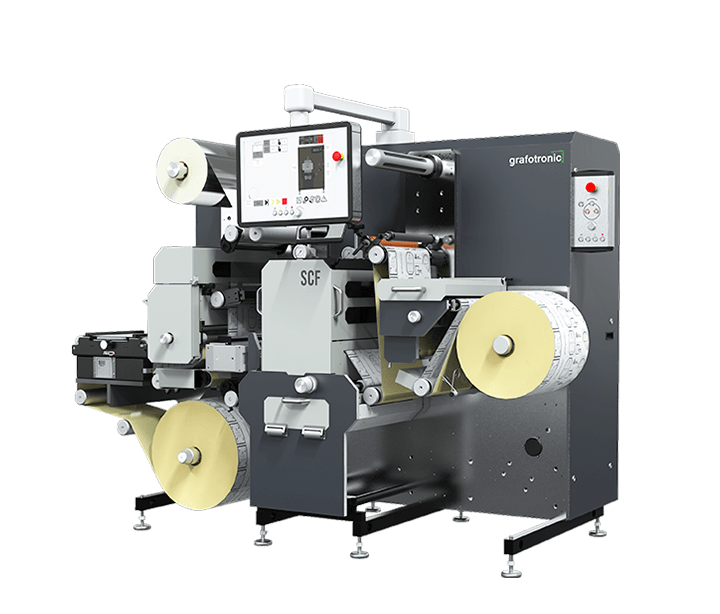

Compact machine, but still high-end and future safe

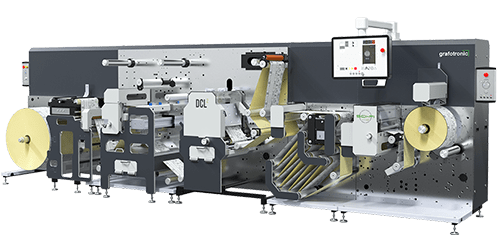

- Machine built on two modules

- Built with the same components as the fully modular DCL2 machine

- The only compact machine that can be extended in the future

- Upgrade on site with any module in just 8 hours

- All our future innovations are available for existing customers

- Innovative, automation features for non-stop production